- Home

- »

- Services

Our online quoting platform and broad range of capabilities make it easy to source custom parts for both prototyping and production.

ISO 9001:2008 |ISO 9001:2015 | IATF16949:2016

Choose a Manufacturing Service

Enhanced Manufacturing Capabilities with Our Digital Network

Our digital network of manufacturers unlocks expanded capabilities across services. To move injection molding from low-volume (10,000+ parts) to higher-volume (100,000+ parts) production, try our network. Anodizing and tighter tolerances are available with CNC machining. And both molding and machining have volume pricing options for lower piece-part cost. You can even prototype quick and cost-efficiently with FDM 3D printing. Get more out of manufacturing with our digital network.

Choose a Manufacturing Service

Manufacturing for the Product Life Cycle

Our advanced manufacturing capabilities and comprehensive material portfolio offer flexible solutions for every stage of product development. Whether you require a single prototype or high-volume production, we serve as your strategic partner, delivering precision-engineered parts with consistent quality, competitive lead times, and exceptional service.

Our Capabilities:

- Rapid Prototyping Services

- Production Support

- Contract Manufacturing

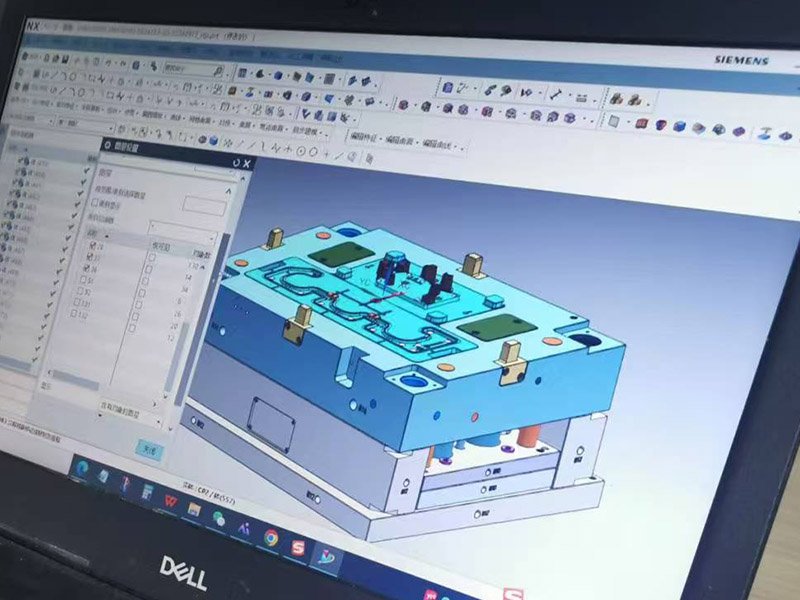

Quoting and Manufacturing Analysis

We recognize that an optimized part design is the foundation of successful manufacturing. Before any production begins, we perform a comprehensive Design for Manufacturability (DFM) analysis—typically delivered within hours of part submission.

This process allows us to identify potential issues early, recommend design improvements, and ensure that every component meets both functional and cost-efficiency requirements.

By addressing manufacturability at the earliest stage, we help our clients reduce lead times, minimize tooling modifications, and achieve superior product quality.

Manufacturing Materials

Select from a wide range of high-performance plastic and metal materials, engineered to meet the demands of both rapid prototyping and full-scale production. Each material is carefully sourced and tested to ensure optimal mechanical properties, dimensional stability, and long-term performance across diverse applications.

ABS, PA6, PA66, PP, POM, PC, TPR, TPEPS, FEP, PVC, PBT.

Carbon Steel, Coated Steel, Stainless Steel, Aluminum & Aluminum Alloy, Copper & Copper Alloy, Special Metal, etc.

Tour our Injection Molding Facility

Gain an inside look at our digitized injection molding process, designed to deliver cost-efficient, high-quality parts with exceptional speed. By integrating advanced automation, real-time monitoring, and precision engineering, we streamline every stage from mold setup to final inspection. This data-driven approach minimizes waste, reduces cycle times, and ensures consistent part quality—empowering you to bring products to market faster while maintaining optimal cost efficiency. Whether for prototyping or large-scale production, our process is built to meet the highest standards of performance and reliability.